In the mining industry, controlling operating expenses (OpEx) is a constant challenge. With the ongoing climate crisis demanding more sustainable practices and environmental regulations tightening, the mining industry has not been immune to the financial challenges of these demanding times and controlling mining OpEx is more important than ever.

With over 15 years of experience working with mining majors across the globe, Cypher Environmental offers solutions that are aimed at reducing mining OpEx while promoting environmentally friendly and sustainable operations. We have found that many companies find adopting sustainable products into their operation can not only help minimize their environmental impact but also deliver significant cost savings. Cypher solutions like ROAD//STABILIZR® and DUST/BLOKR® are designed to decrease maintenance, fuel, water, and labour costs, all while supporting corporate sustainability goals.

In the case of our customer, Shenhua Beidian Shengli Energy Co. Ltd., their coal mine near Xilinhote experienced a quantifiable 17.4% reduction in diesel fuel consumption on Cypher-treated haul roads versus untreated roads. This equated to a savings of approximately USD 3.6 million during that timeframe. CO2 emissions were also reduced by over 10,000 tons/year. In this article, we will cover the ways that the implementation of Cypher’s solutions can help decrease your mining operating costs.

What is Mining OpEx?

Operating expenses (OpEx) in the mining industry refer to the recurring costs that are associated with operating a mine. Mining OpEx can include both direct and indirect costs related to mining, processing and selling of the minerals.

Costs like haulage expenses and the ongoing maintenance of haul roads are considered an operating expense and can make up a significant portion of a mining operation’s operating expenses. Downtime, vehicle failure, and worker injury can all contribute to added expenses with dire consequences.

How can ROAD//STABILIZR and DUST/BLOKR help to reduce mining OpEx?

1. By reducing your rolling resistance

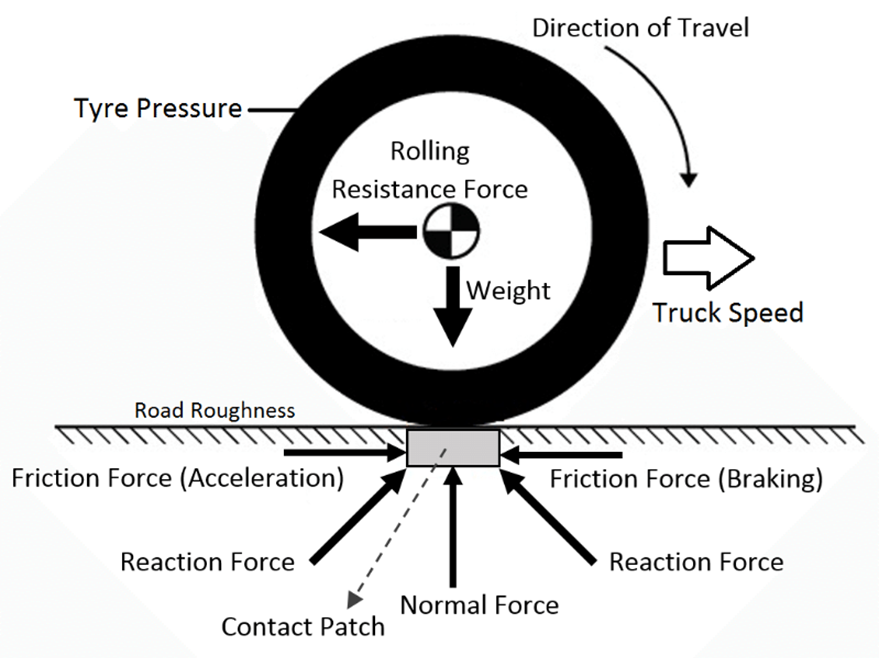

Rolling resistance refers to the force (energy) required to accelerate and maintain a constant speed over a given surface. Rolling resistance is measured in Newtons (N). On road surfaces, rolling resistance is created by the combined force of the deformation of the tires and the deformation of the running surface. To understand rolling resistance, imagine the physical resistance you feel as you drive across a hard packed surface versus a muddy or sandy surface.

Harder roads with less deflection can mean getting from point A to point B faster, which leads to an increase in cycle time efficiency on industrial haul roads.

When rolling resistance and deflection are reduced, it also means that less energy is required to transport that same load from point A to point B, therefore reducing fuel consumption of haul trucks and helping to improve overall fuel burn efficiency.

Key benefits:

- Fuel Efficiency: Stabilized roads require less energy for transport, reducing fuel consumption

- Increased Efficiency: Haul trucks can move faster between points, improving cycle times and boosting overall productivity

2. Create more reliable and safe roads with fewer maintenance needs

The use of Cypher’s DUST/BLOKR® and ROAD//STABILIZR® leads to longer-lasting roads, increased road strength and reduced airborne dust. This reduces the need for continuous grading and cuts down on the number of maintenance vehicles required. Additionally, DUST/BLOKR® not only controls airborne dust but can also contribute to road stabilization, further reducing maintenance demands.

DUST/BLOKR® reduces airborne dust, operators will have a much more clear line of sight, leading to fewer accidents and injury.

Key benefits:

- Reduced Haul Road Maintenance Requirements: Less frequent grading means fewer resources spent on road maintenance.

- Reduced Capital Expenditure: Reduced maintenance on equipment and assets, lowering capital expenses (CapEx) over time.

3. Reduce labour costs

Sustainable solutions like DUST/BLOKR® and ROAD//STABILIZR® can reduce the amount of time and labour required for road maintenance. With fewer vehicles out of service for repairs and maintenance, there is less need for manpower. Safer driving conditions also mean better conditions for operators on the road.

Key benefits:

- Fewer workers required: lower maintenance frequency means reduced staffing needs

- Reduced operator costs: operations are more streamlined, requiring fewer operators to manage both vehicles and equipment

4. Reduce fuel consumption

Sustainable road products like Cypher’s DUST/BLOKR® and ROAD//STABILIZR® help reduce rolling resistance and improve road conditions, which in turn leads to reduced fuel consumption. Fuel is one of the largest operational expenses for mining companies, and any reduction in fuel use directly impacts the bottom line.

A prime example is our customer, the Shenhua Beidian Shengli Energy Co. Ltd. experienced a a quantifiable 17.4% reduction in diesel fuel consumption at one of their operations after the application of Cypher products. The Shenhua Beidian Shengli Energy Co. tracked the performance of Cypher-treated mine haul roads for a period of 1 year after application. The results can be found in their abstract, available for download here.

Shenhua Coal Mine experienced a 17.4% reduction in diesel fuel consumption after the application of ROAD//STABILIZR® and DUST/BLOKR® on their haul roads.

Key benefits:

- Lower carbon emissions: reduced fuel consumption means fewer greenhouse gas (GHG) emissions, aligning with sustainability initiatives

- Smaller carbon footprint: by consuming less fuel, mining operations contribute to the fight against climate change

5. Increase tire and equipment lifespan

One of the overlooked benefits of using soil stabilization and dust control products for mine haul roads is the increased lifespan of both tires and machinery. Smoother, more stable roads reduce wear and tear on tires, which are a significant annual expense in mining operations. Additionally, reduced dust levels mean equipment components, such as filters and moving parts, need to be replaced less frequently.

Key benefits:

- Longer tire life: better road conditions translate to fewer tire replacements, saving thousands in operating costs

- Fewer equipment breakdown: less dust accumulation reduces the wear on equipment, lowering repair and replacement costs

6. Reduce water consumption

Water is commonly used in the mining industry to control dust, but it is a resource-intensive and costly method. In some regions of the world, water scarcity is also a major concern. According to the World Wildlife Foundation, based on current water consumption rates, approximately half of the world’s population will face water shortage by 2025.1 Currently, 2.2 billion people worldwide lack access to safe drinking water2 and in sub-Saharan Africa, 1 in 3 people face water scarcity and do not have enough water to meet their daily needs.3

Water conservation is becoming increasingly important, as global water shortages loom. By using sustainable dust control products that are longer-lasting, mining companies can reduce their water usage and OpEx while helping to alleviate water scarcity concerns.

Even when water is inexpensive to purchase, the continuous costs of watering roads – the cost of hauling water, fuel, operating a fleet of water trucks, interruptions to mining operation – can all add up overtime.

7. Reduce airborne dust and limit dust-related health hazards

Excessive dust is a common issue on mine haul roads, as most of these types of roads are unpaved. Airborne dust can affect visibility and increase the risk of accidents. It can also have serious health implications for miners if inhaled over a long period of time. A sustainable dust control product such as Cypher’s DUST/BLOKR® can not only reduce dust, but also yield better and longer lasting protection.

Key benefits:

- Improved air quality: reduced dust minimizes the risk of respiratory issues for miners working on-site

- Enhanced safety: with better visibility, haul trucks can move faster and more safely, improving cycle time and reducing the likelihood of accidents.

8. Reduce logistics and shipping costs

Unique to Cypher Environmental, our sustainable and environmentally friendly products are highly concentrated and are only mixed with water prior to application. This means that less product is needed in order to achieve the same results. This further leads to fewer shipments, reducing your logistical costs even before the product reaches your site.

Pictured here is our 10 L jugs of ROAD//STABILIZR product. Just 1 of these jugs can effectively treat 330m3 of road material.

Sustainable and Environmentally Friendly Products can help reduce Mining OpEx

Therefore, incorporating sustainable and environmentally friendly road stabilization and dust control products into mining operations can not only help reduce the environmental footprint of mining, but can also be a powerful strategy for reducing mining OpEx.

From reducing fuel and water usage to lowering labour and maintenance costs, Cypher’s innovative soil stabilization and dust control products offer comprehensive solutions that benefit both the environment and the bottom line.

If you want to know more about our dust control products you can read more on DUST/BLOKR® and ROAD//STABILIZR® on our website, or contact us here.

Sources

- Unicef Data: July 2023 Universal access to safe drinking water is a fundamental need and human right.

- United Nations Global Issues Water

- World Health Organization African Region: Health Topics Water

Originally posted November 13, 2019 and updated for relevance September 2024.