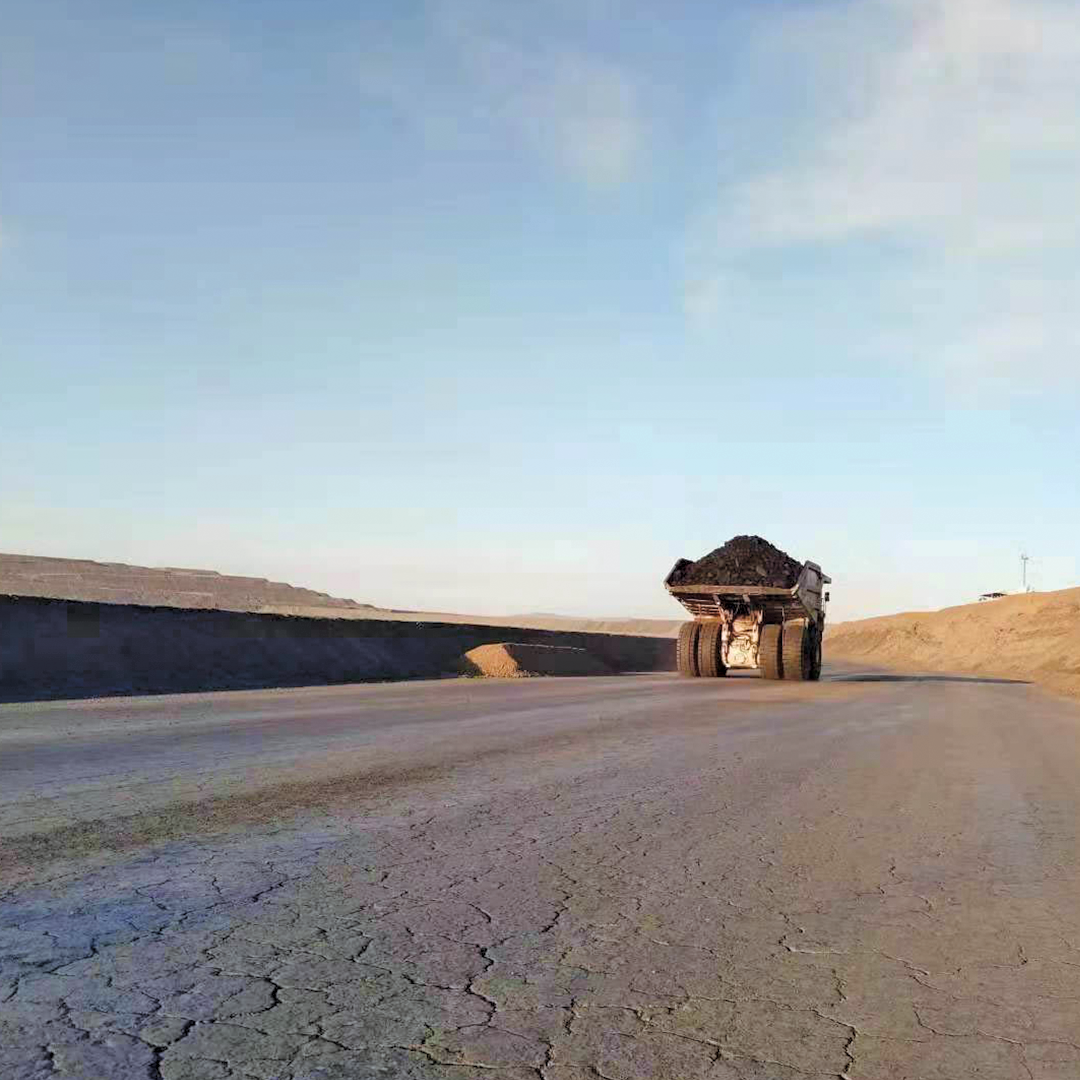

ROAD//STABILIZR® is a long-term soil stabilization solution for roads that require continual maintenance due to wet weather and marginal road materials. ROAD//STABILIZR® targets soils with high clay content by increasing density and providing enhanced stability and strength.

ROAD//STABILIZR® is biodegradable, non-toxic, non-corrosive and is specifically engineered to work on high clay content soils, which would normally be considered marginal in terms of their engineering properties. The product allows for the use of these types of in-situ materials providing substantial cost savings over traditional materials for road building, such as aggregate.

The roads built with ROAD//STABILIZR® are stronger, more dense and stable – proven to be effective in both wet and dry conditions and during freeze-thaw cycles.