Clay is an abundant resource that can be found in many parts of the world. However, as a road-building material, it is highly problematic. Clay tends to swell and lose strength with moisture followed by contraction when it dries, causing cracks and surface erosion and leading to subgrade failures. These fluctuations require frequent and costly maintenance, ultimately draining road budgets year after year. So, how can we overcome these challenges in building strong clay roads?

The Challenges of Building Strong Clay Roads

While clay is an abundant resource, its natural properties can cause significant problems when used untreated for road construction. The main issues include:

- Swelling and Shrinking with Moisture: one of the most problematic aspects of untreated clay is its reaction to moisture. When exposed to water, clay particles absorb moisture and expand. This causes the road surface to swell, weakening the overall structure of the road. As it dries, clay contracts, creating cracks and weak spots. This cycle of expansion and contraction causes the road to lose its stability and load-bearing capacity, making it prone to ruts, potholes and surface deformation.

- Poor Load-Bearing Capacity: untreated clay roads often have low strength (as mentioned above) and low density. This means that the roads are not able to support heavy loads or high-volume traffic, causing it to deteriorate faster.

- Erosion: with the constant cycle of expansion and contraction, untreated clay loses its integrity – in wet conditions, the clay can create muddy road conditions or wash away while in dry conditions, the clay can become brittle and break away.

- Dust Concerns: with the break-away of clay particles in dry conditions, airborne dust can affect air quality, impact the health of people living nearby or creating unsafe driving conditions.

These challenges with the fundamental makeup of clay results in 1) Lack of durability and 2) Higher Maintenance Costs. The inherent instability of untreated clay roads means they need constant attention – whether it is to strengthen the road, regular grading or applying dust control. All this translates into significant long-term maintenance costs, coupled with the cost of water or product (for dust control), fuel consumption, road closures, health and safety issues, and labour makes untreated clay extremely ineffective road building material.

Building a New Clay Road

The general solution for building roads is to bring in gravel or other aggregate that is more suitable for construction. This material would need to be crushed, hauled, and laid.

However, this approach only offers a short-term fix. For roads with a high in-situ clay content, the added gravel or aggregate would eventually sink into the clay due to the constant cycle of expansion and constriction. Additionally, gravel is susceptible to erosion caused by rain runoff and traffic wear. Consequently, more gravel would have to be added (typically every 1 – 2 years).

Without treatment, the untreated clay road would continue to erode, causing the same issues to mentioned above to recur, leading to ongoing maintenance and increased costs.

The Solution: Building Strong Clay Roads with ROAD//STABILIZR®

One advantage of using clay as your road building material is that it is already on-site and available abundantly. To challenge would be to find a way to utilize the clay, optimizing its natural characteristics.

Cypher Environmental’s ROAD//STABILIZR® offers a game-changing solution to the problem of clay-based road building. Unlike traditional stabilizers, ROAD//STABILIZR® is designed specifically to enhance the properties of in-situ clay, increasing its strength and density while reducing its natural swell potential. This liquid product is applied directly to the road surface, where it bonds with the clay particles, transforming them into a more durable material that resists erosion and wear.

When applied to clay, ROAD//STABILIZR® increases the California Bearing Ratio (CBR), which measures a material’s strength and ability to support traffic loads. The result is a road base that is stronger and more resistant to wear. What sets ROAD//STABILIZR® apart from other stabilizers is its ability to retain the clay’s self-healing properties. Cracks that form in the road surface can be naturally sealed with water and compaction, meaning the road can repair itself over time, reducing the need for expensive repairs.

One of the most notable benefits of using ROAD//STABILIZR® is that it eliminates the need for gravel or crushed rock. This reduces the logistical challenges and costs associated with hauling and laying new materials. With ROAD//STABILIZR®, you can use the clay that’s already on-site, significantly lowering the overall cost of road construction and maintenance.

The Financial and Environmental Benefits of Building Strong Clay Roads with ROAD//STABILIZR®

The financial savings provided by ROAD//STABILIZR® are substantial. When constructing a new road, you typically need to import large quantities of gravel or other aggregates. This process involves hauling materials over long distances, which not only increases the cost of construction but also has a significant environmental impact. The fuel used to transport these materials contributes to carbon emissions, and the extraction of gravel or rock can degrade the local environment.

By stabilizing in-situ clay, ROAD//STABILIZR® eliminates the need for these costly and environmentally harmful materials. Instead of spending money on hauling gravel and dealing with the associated environmental impacts, you can use local clay to create a strong, durable road base. ROAD//STABILIZR® can stabilize one kilometer of secondary road with just 40 liters of product—about the size of a trunk full of liquid. This significantly reduces transportation costs, and because you’re using locally sourced clay, you’re helping to preserve natural resources as well.

ROAD//STABILIZR® Real Life Success

RM of Cornwallis

The success of ROAD//STABILIZR® is not just theoretical—it’s already being demonstrated in real-world applications. Take, for example, the RM of Cornwallis, where several roads have been treated with the product. One such road, Currie’s Landing, was a problem child. Due to heavy traffic from nearby gravel quarries, it needed to be watered 2-3 times per day, graded twice a week, and treated with chlorides for dust control every two weeks.

After switching to ROAD//STABILIZR®, the municipality saw immediate results. Watering was eliminated entirely, and grading frequency dropped to just once per year. The savings were staggering—over $40,000 annually in watering alone. These savings allowed the municipality to divert resources to other important infrastructure projects and social programs. This example clearly demonstrates how a small investment in ROAD//STABILIZR® can result in huge returns, freeing up valuable resources for other areas.

Shenhua Open-Pit Coal Mine

The Shenhua open-pit coal mine is located in Xilinhot, Inner Mongolia. The mine was looking for a soil stabilization solution to enhance and strengthen its vast network of transport roads. Specifically, the mine was looking for a solution that could:

- Work with the in-situ clay materials to avoid bringing in expensive aggregate

- Perform in a cold and semi-arid climate

- Be easily transported to the mine’s northern remote location

- Be environmentally friendly and allow for future ecological restoration efforts to take place

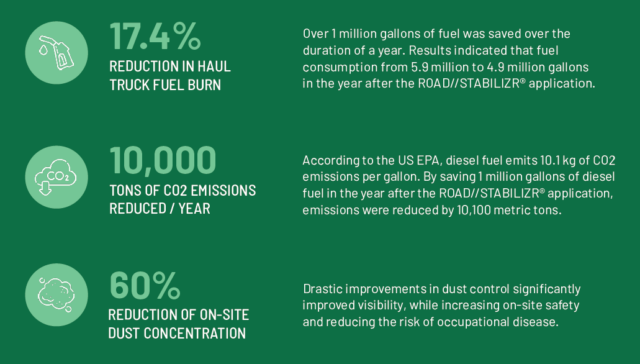

The mine first trialled the ROAD//STABILIZR® solution on a 500 m stretch of haul road and monitored its performance over the course of one year. Not only did ROAD//STABILIZR® performed as intended, the research also showed favourable results across 3 success metrics – reduction of haul truck fuel burn in litres and dollars, the amount of CO2 emissions reduced and the amount of airborne dust reduced.

Whether you’re building a new road or maintaining an old one, ROAD//STABILIZR® offers a smart, cost-effective, and environmentally friendly solution. By stabilizing in-situ clay, you can build strong, long-lasting roads without the high costs and environmental impacts associated with transporting gravel. The long-term savings in maintenance, dust control, and repairs will significantly reduce the overall cost of your road infrastructure.

If you’re ready to lower your road construction and maintenance costs, boost the durability of your roads, and make a positive impact on the environment, contact us today to learn more about how ROAD//STABILIZR® can transform your clay roads into a reliable and cost-effective asset.